Description

EPDM Rubber Tube Trade Information

- Minimum Order Quantity – 300 Kilograms, ,

- Supply Ability – 2 Kilograms, , Per Day

- Delivery Time – 2-3 Days

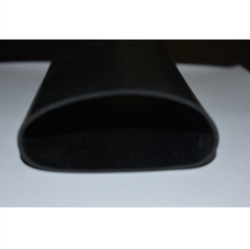

About EPDM Rubber Tube

Established in year 2012, our company has emerged as one of the trusted manufacturers and suppliers ofEPDM Rubber Tube. This tube is made using high grade rubber which is procured from reliable market vendors. It is often used for automotive applications such as windshield washers, heater/coolant hose, vacuum-operated accessories ad emission systems. Before final dispatch, it is checked on different standard parameters by our experts in order to deliver defect free range.EPDM Rubber Tubeis also available in different specifications at affordable market prices.

Features:

- Resistant to heat

- Smooth surface finish

- Highly flexible

Product Details :

| Color | Black |

| Brand | GRU |

| Size | As Required |

| Packaging Type | As Required |

| Material | EPDM |

| Unit Length | 1mm-150mm |

| Shape | As Requird |

| Tensile Strength | As Requird |

| Usage/Application | Heat Resistant |

| Elongation | As Requird |

| Temperature | As Requird |

| Weight | As Requird |

| I Deal In | New Only |

| Country of Origin | Made in India |

Superior Environmental Resistance

Our EPDM Rubber Tube excels in ozone and UV resistance, offering superior durability outdoors. The material resists cracking even after prolonged exposure to harsh weather, making it ideal for environments requiring long-lasting performance. Whether installed in automotive or industrial systems, this tube remains flexible and robust against environmental stressors, outlasting many conventional hose types.

Customizable for Diverse Applications

Manufactured through an extrusion process, these tubes offer flexibility in both dimension and application. Inner diameters from 1/8 to 2 inches and wall thickness from 1 mm to 10 mm can be customized to meet specific needs. EPDM tubes are extensively used in automotive, water, air, and industrial systems for efficient sealing and fluid transfer, supporting pressure requirements up to 10 bar.

Safe and Reliable Material Compliance

The EPDM tube is crafted from 100% synthetic rubber with negligible nitrogen content, ensuring a low volatile matter percentage and ash content below 1%. Meeting RoHS compliance and ASTM D2000 standards (upon request), it presents a safe option for industries where environmental compliance and product reliability are critical.

FAQs of EPDM Rubber Tube:

Q: How should EPDM rubber tubing be installed for optimal performance in outdoor applications?

A: For best results outdoors, ensure the tube is installed away from sharp edges or abrasives. Its excellent weather and ozone resistance make it ideal for exposed environments, but proper support and routing will maximize service life. Always verify the tubes dimensions and thickness match your application requirements.

Q: What are the main benefits of using EPDM rubber tubes compared to natural rubber hoses?

A: EPDM rubber tubes offer superior ozone, weather, and aging resistance, as well as better performance with weak acids and alkalis. They withstand a broader temperature range (-40C to +120C, temporarily up to 150C), have low water absorption and excellent longevity, especially in outdoor or demanding environments.

Q: When is it appropriate to use EPDM rubber tubing over other types of hoses?

A: EPDM tubing is the preferred choice when you need excellent resistance to ozone, UV exposure, weathering, and mild chemicals. It is ideal for automotive, industrial sealing, coolant, water, and air/vacuum applications where these properties are critical.

Q: Where are EPDM rubber tubes commonly applied?

A: These tubes are widely used in the automotive industry for coolant and water transfer, air and vacuum lines, and industrial sealing. They are also suitable for general fluid transfer in environments requiring good electrical insulation and chemical resistance.

Q: What manufacturing process is used for EPDM rubber tubes, and how does it affect quality?

A: The tubes are produced via extrusion, resulting in a flexible, smooth, and uniform product. This process allows for precise control over dimensions and surface finish, ensuring tubes are free from porosity, blisters, and other defects.

Q: What standards and compliance certifications are available for your EPDM rubber tubes?

A: Our tubes meet RoHS compliance and conform to ASTM D2000 standards upon request, providing assurance of quality, environmental responsibility, and suitability for a range of regulated industries.

Reviews

There are no reviews yet.